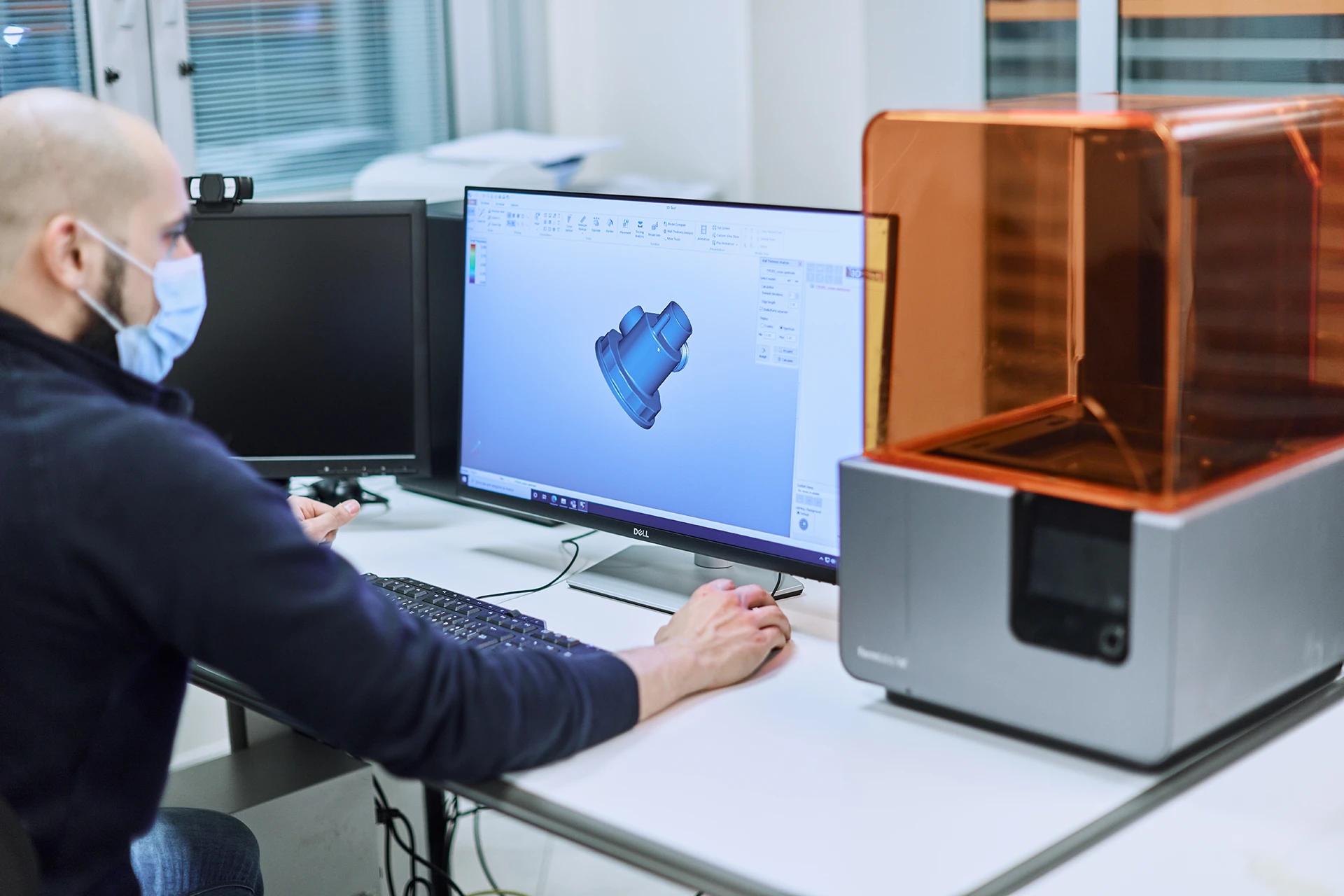

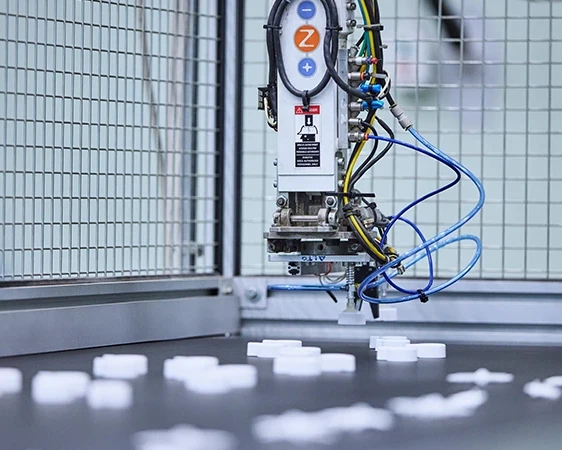

Tailor-made solutions for plastic moulding

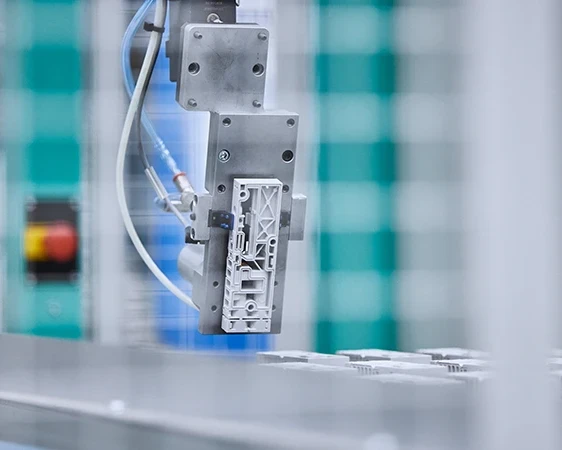

In Teksae we are specialized in plastic molding through the injection technique. We offer tailor-made solutions for the production of high quality plastic components, suitable for various industrial applications. Thanks to the experience of our team and the use of advanced technologies, we guarantee precision, efficiency and attention to the environment in every project.

Advice

Whether it’s choosing compounds or post-moulding procedures, we support companies in the production of plastic components for diverse application requirements.

Experience

Even the smallest component affects the quality of your products. We’ll help you source the right plastic for your items.

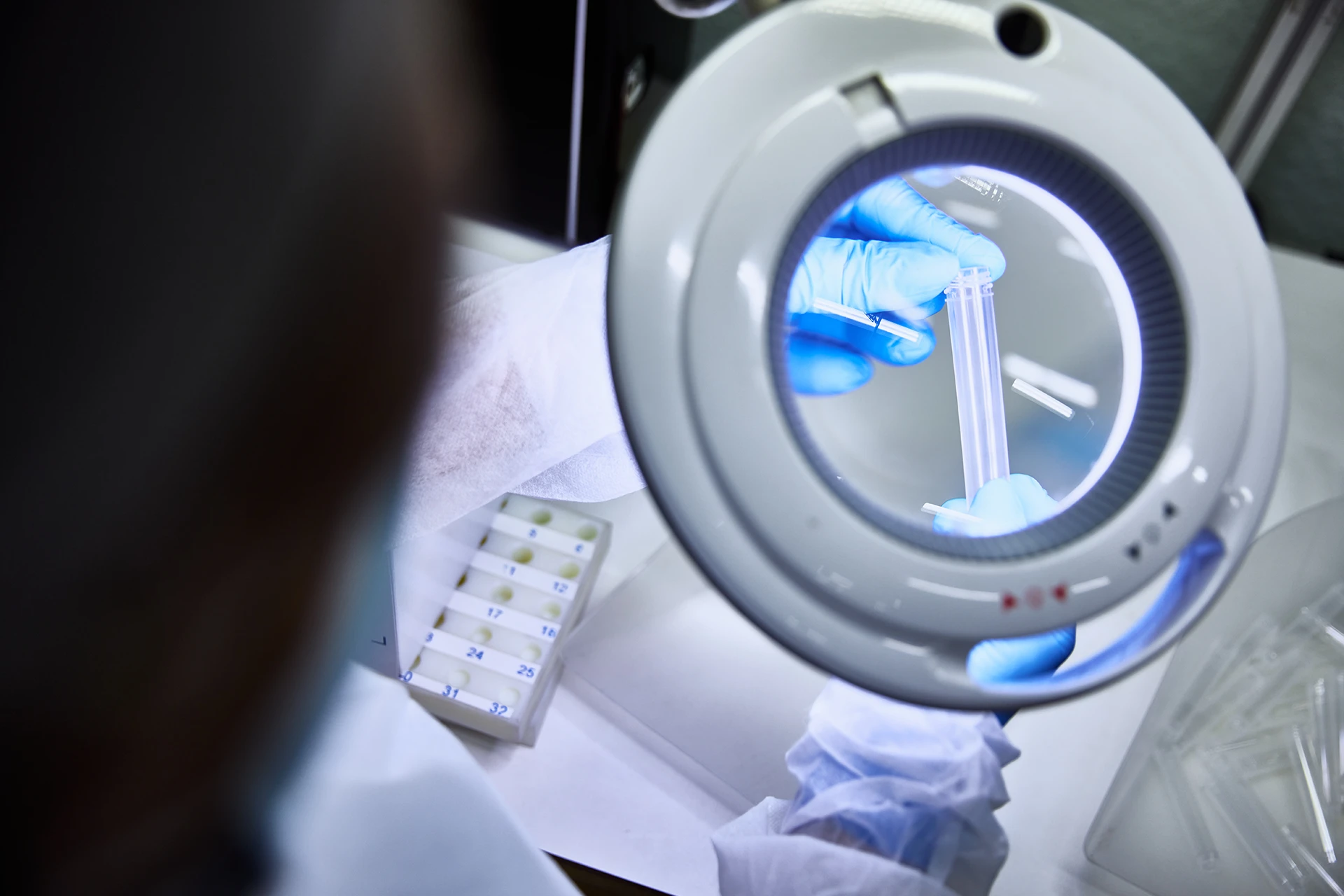

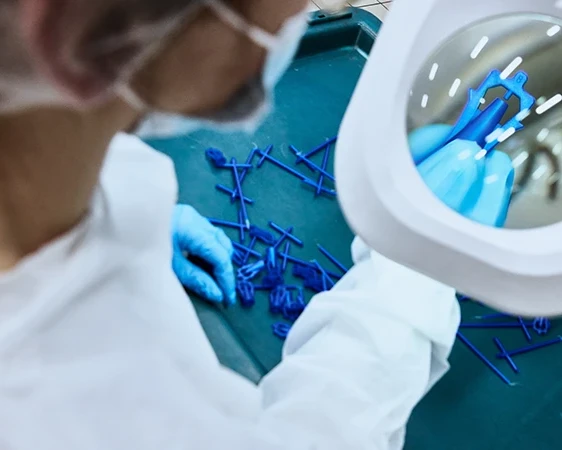

Quality

We carry out regular checks, track every batch, and maintain high standards of hygiene for the food and medical sectors.

Application sectors

With more than 20 years of experience in plastic moulding, we can meet the requirements of any industry, from the production of valves through to the automotive, furniture, heating and plumbing sectors.

The hygiene level in our production department makes us suitable for working with the food and medical sectors, and we hold ISO 13485 certification and meet all Italian food safety requirements (M.O.C.A.). Our customers include mould manufacturers who rely on us to validate their moulds and test batches, and companies seeking a competent, reliable supplier to collaborate in the design and production of new solutions.

In over 4000 m2 of covered premises we have 19 injection moulding machines (Arburg and Fanuc) for single and dual-material parts.

The production departments have been built and equipped with control systems that keep the environment healthy, also allowing the production of plastic components for the food and medical sectors. Our specialist technicians fully understand the pros and cons of every compound, and will help you to find the most suitable solution to create plastic components that exceed your expectations.

260Mln

pieces produced 2023

580T

Raw material used 2023

Standards and Certifications

We print plastic in compliance with the regulations provided for by certifications

Plastic molding certified

ISO 13485

Plastic molding certified

ISO 9001

Plastic molding certified

ISO 14001

Plastic molding certified

Food-M.O.C.A.

Plastic materials for plastic moulding

Thanks to our in-depth knowledge of the characteristics of each plastic material, we can process over 60 different compounds, choosing the most suitable one according to the application needs.

Environmental protection in plastic moulding

In TEKSAE we have reduced the impact of plastic molding on the environment, implementing 100% green energies, latest generation full electric machines and a ISO 14001 certified environmental policy.